Recipes and tips for professional pasta extruder

How to make fresh pasta with professional pasta maker

Here you can find recipes and instructions for use of our pasta extruders. Actually, we decided to list on this page different suggestions, which we often give to our customers. Each year we distribute hundreds of hand-crafted pasta machines: that can be considered as a synonymous with reliability, high quality and accuracy.

Each single pasta machine is conceived to meet each kind of request: long and short pasta cuts, filled pasta, gnocchi, cannelloni, puff pastry, and many other pasta shapes.

Use of our professional fresh pasta extruder

Once the die has been fixed with the special metal ring and the ingredients have been put inside the pasta maker, the inverter must be moved to the KNEADS position and the kneading operation can start by pressing the button 1.

After around 7-9 minutes, it is necessary to press the button 0, turn the inverter into the EXTRUDES position and press button 1 once again.

Please, kindly note that after about 3 minutes of use, the temperature of the electric engine reaches the temperature of 55-60 ° degrees.

Therefore, it is absolutely correct and normal that the engine becomes warm.

Dough and Ingredients

Before proceeding with the extrusion of the dough, we suggest you to check the consistency of the dough: it should be grainy like rice grains, neither too hard nor too soft.

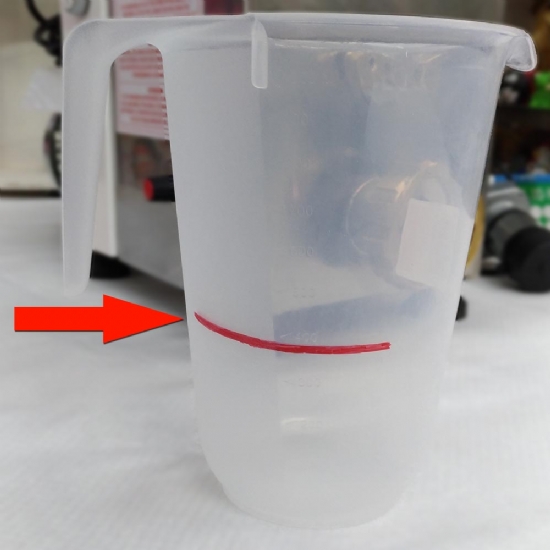

In order to obtain the ideal dough, please keep in mind that you need about 400ml of liquid (eggs, water, vegetable purée, etc.) for every kilo of flour. For this reason, our pasta makers are supplied with a transparent dispenser, which is intended for food contact and made of rigid plastic. The red mark on it indicates the amount of liquid, which is necessary for every kilo of flour (see Figure A).

For the dough, you can use any kind of flour such as durum wheat, gluten-free flour, super-fine flour, semolina or mixed wheat flour-semolina.

Actually, one of the doughs most frequently made with the pasta maker La Fattorina consists in 600gr of super-fine flour, 400gr of semolina and about 7 eggs. In case you have not reached the red mark of the dispenser after having inserted the indicated 7 eggs, we suggest you to add some water. Indeed, people who prefer to use fewer eggs, should top up the dispenser with water, until the usual red mark is reached.

As for the use of gluten-free flour, we recommend using about 350 grams of eggs and 50 grams of water for every kilo of flour.

Gnocchi can be produced only using the appropriate die and the lyophilized potato flour. Fresh potatoes cannot be used, since they could damage the machine itself. We suggest you to use 500gr of lyophilized potato flour and about 320cc of water for each gnocchi dough.

Dies and Cleaning Indications

All dies must be inserted and fixed manually, that is to say, with the sole force of the hands, before starting the machine. However, during the extrusion phase, the operator can stop the machine at any time using the appropriate button 0 and then replacing the die in order to produce different pasta shapes.

In the user manual, we have published, in addition to the drawing of the die itself, a second real photo of the die. (see Figure B)

To clean the dies, it is sufficient to dip them in a container full of water (see Figure C). In this way, the pasta leftovers remain soft and are easily removable.

As concerns the cleaning of the steel tank, we recommend using a damp cloth and carefully cleaning the extrusion hole of the dough (see Figure D)

Actually our pasta machines are able to meet each kind of specific demand: from the familiar use, to the small catering service, up to the needs of the big pasta factories . With this pasta machine, which meets each kind of customer's need, you can produce almost completely the entire range of pasta shapes.

Last but not least. Our pasta makers have another strong point: 3 years warranty. Their high quality and solidness allow us to guarantee them for three years.

|

|

Type - La Fattorina

Power: 0,4kw - Monofase

Tank Capacity: 1,5kg

Production per hour MAX: 4kg

Weight of the machine: 20kg

Dimensions: 20X48X29cm

Type - VIP2

Power: 0,6kw - Monofase

Tank Capacity: 3kg

Production per hour MAX: 9kg

Weight of the machine: 38kg

Dimensions: 26X60X35cm

Type - VIP4

Power: 0,8kw - Trifase

Tank Capacity: 4kg

Production per hour MAX: 14kg

Weight of the machine: 45kg

Dimensions: 28X65X45cm

Type - Compatta

Power: 1kw - Trifase

Tank Capacity: 8kg

Production per hour MAX: 24kg

Weight of the machine: 80kg

Dimensions: 38X62X75cm